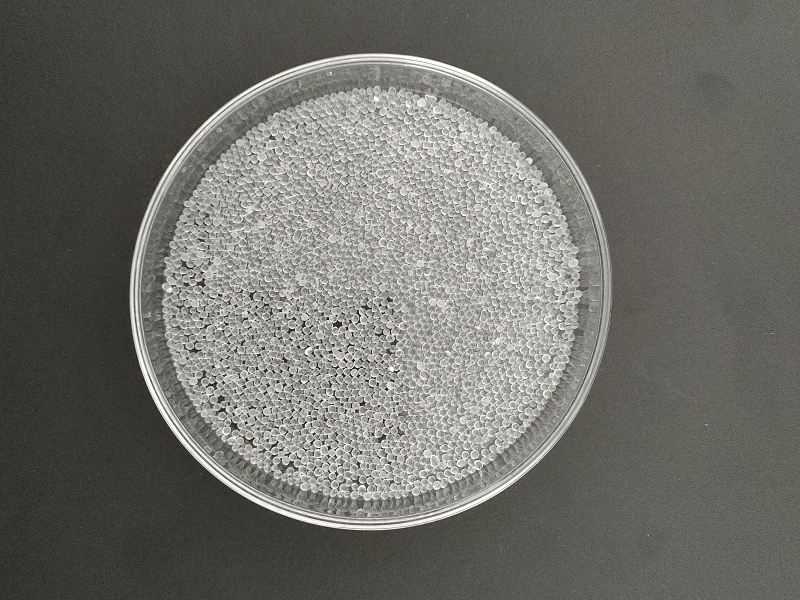

1. Filler material: Glass microspheres are widely used as filler materials in fields such as chemical engineering, construction, plastics, and rubber. They can fill the gaps in the material, improve density and strength. In addition, they can also reduce the weight of materials, improve their fluidity and processing performance.

2. Insulation material: Due to the low thermal conductivity and electrical conductivity of glass microspheres, they are used as insulation materials. They can be used to manufacture insulation boards, insulation coatings, insulation films, etc., and are used in the fields of electronics, electrical engineering, and construction. Glass microbeads can effectively insulate heat and electricity, improving the safety of equipment and buildings.

3. Coatings and paints: Glass microspheres can be used as fillers in coatings and paints. They can increase the hardness and wear resistance of the coating, improve the gloss and transparency of the coating. In addition, glass microspheres can also reduce the shrinkage and cracking of coatings, improve the leveling and adhesion of coatings.

4. Road markings: Glass microbeads are widely used in the manufacturing of road markings. They can be mixed into road paint to give road markings high reflectivity and durability. Glass microbeads can reflect the headlights of vehicles at night, improving the safety of nighttime driving.

5. Aerospace: Glass microspheres also have important applications in the aerospace field. They can be used as reinforcing materials for lightweight composite materials, improving their strength and stiffness. In addition, glass microspheres can also be used to manufacture insulation layers for spacecraft, reducing heat conduction and radiation.

Glass microbeads have various functions such as filling materials, insulation materials, coatings and paints, road markings, aerospace, etc. They play an important role in various fields, and their application scope will be further expanded in continuous research and development.