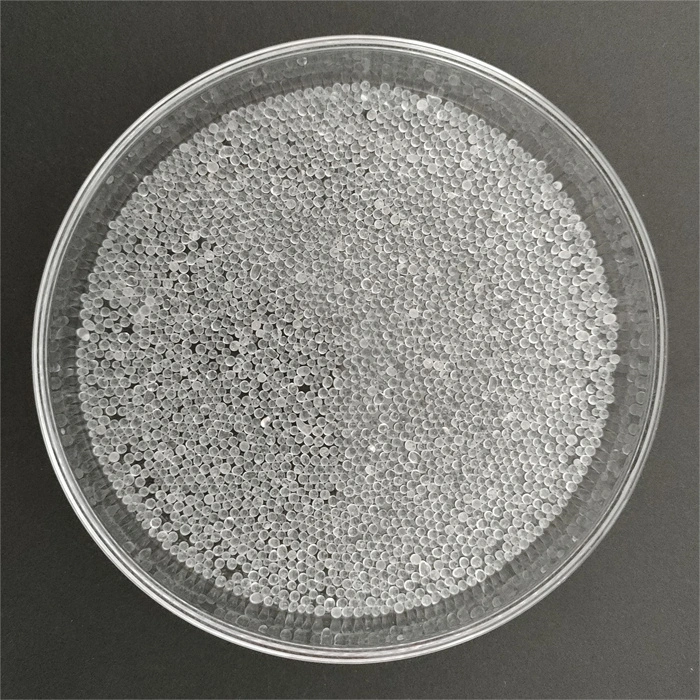

Glass Micro Beads Blasting Media

Glass beads are made from glass as raw material, which is specially crushed and sintered. They have the characteristics of smoothness, smooth surface, uniform size, high hardness, wear resistance, and good stability. Widely used as dispersants, grinding media, and filling materials in industries such as dyes, paints, inks, and chemicals.

We provide all specification of glass beads and can customize products according to your requirements. Welcome consulting.

Glass microbeads are produced from high-quality glass and have a certain mechanical strength. The SiO2 content is higher than or equal to 68%, and the hardness can reach 6-7 Mohs. They also have sufficient elasticity and can be used repeatedly, making them less prone to breakage.

Glass microbeads can be used for industrial machinery sandblasting and shot peening treatment. Including: surface matte treatment of stainless steel products, cleaning of various molds, removing tensile stress from various components, increasing fatigue life, cleaning and removing edge thorns before tin plating on semiconductor devices, plastic packaging tubes and medical equipment, etc.

Main Index

| Technical parameters | |||

| Product Name | Glass Beads | ||

| Product Number | TR-120 | ||

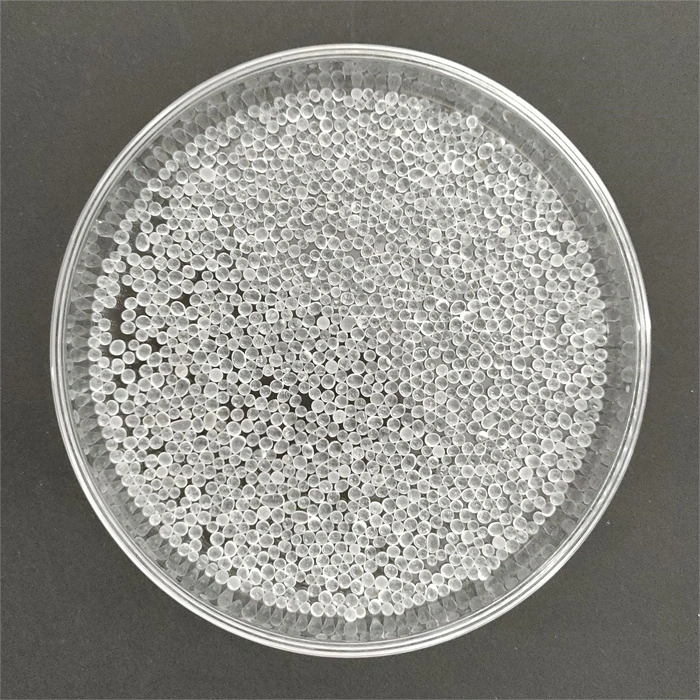

| Appearance | Colorless, transparent, approximate circle sphere, rounded and smooth, no obvious bubbles or impurities |

||

| Chemical Composition | soda lime glass, SiO2 content of> 68% | ||

| Circularity | Density | Refractive index | Mohs hardness |

| round rate of ≥ 90% | 2.5g/cm3 | Nd ≥ 1.50 | 6-7 |

| Mechanical properties | Microhardness | Acid resistance | alkali resistance |

| compressive strength 3300kg/cm2 |

8000kg/cm2 | 20% HCI solution in 4 hours boiling loss 0.005Mg /cm |

alkali solution in 1% NaOH loss 0.3mg/cm3 boiled four hours |

| Detail of product | |||

| Grinding glass beads is made of glass as raw material by crushing particular, sintering, with a smooth surface, uniform size, high hardness, wear resistance, stability and other characteristics. Widely used in dyes, paints, inks, chemical and other industries dispersant, grinding media and filler material |

|||

| Size(mm) | Round rate | Product no. |

| 0.6-0.8 | 95% | TR-0608 |

| 0.8-1.0 | 95% | TR-0810 |

| 1.0-1.5 | 95% | TR-1015 |

| 1.5-2.0 | 95% | TR-1520 |

| 2.0-3.0 | 90% | TR-2030 |

| 3.0-4.0 | 90% | TR-3040 |

| 4.0-5.0 | 90% | TR-4050 |

| 6.0 | 100% | TR-60 |

Trade details

| MOQ | 500 KGS |

| Payment | 30% as deposit, and balance paid before shipment |

| Place of origin | Shandong, China |

| Lead time | 20-30 days |

| Shipment port | Qingdao, China |

| Trade terms | FOB, CFR, CIF |

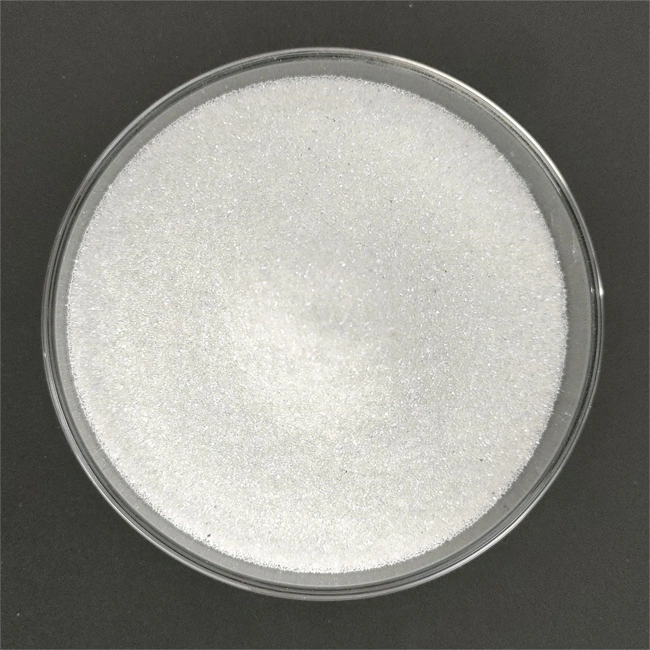

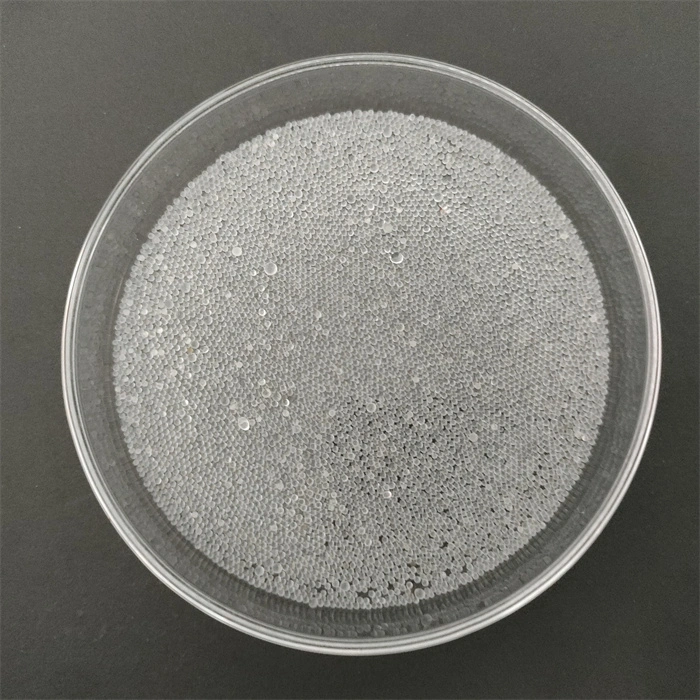

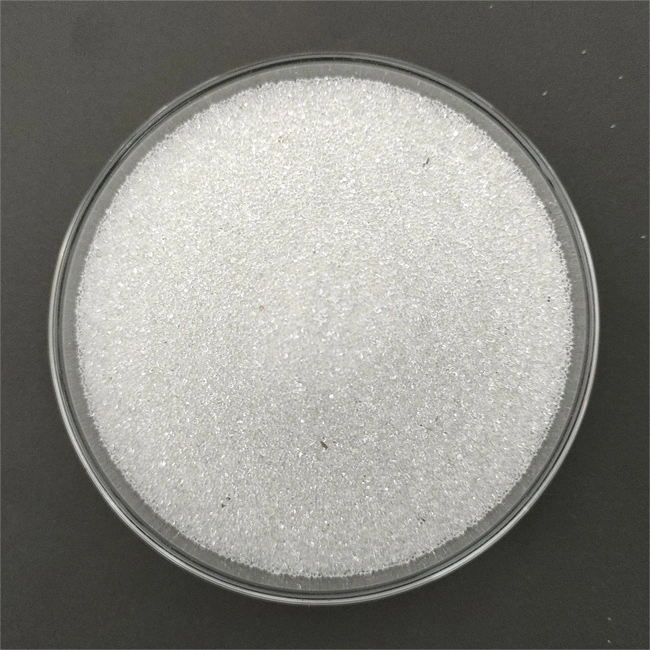

Specification display

Application

Surface treatment and painting

Glass beads are often used in surface treatment and coating applications to enhance the texture and appearance of coatings. They can be used as additives to make the coating smoother, more uniform, and provide better coverage and reflectivity.

Grinding and polishing

Due to the moderate and uniform hardness of glass beads, they are widely used in the field of grinding and polishing. For example, in metal processing, they can be used to remove surface oxide layers and dirt, providing a bright surface.

Fillers and reinforcing materials

Glass beads can be used as fillers to increase the volume of materials and improve physical properties. In the fields of polymers, composite materials, and cement, they can improve the strength, stiffness, and wear resistance of materials.

Reflective material

Due to the smoothness and reflective properties of the surface of glass beads, they are commonly used in the manufacturing of reflective materials, such as reflective coatings, reflective signs, and traffic markings. Under lighting conditions, these microspheres can increase visibility and safety.

Factory display

FAQ

Q1:Do you accept customized products?

A: Yes, we accept customized products, we can design and produce new products depend to your needs.

Q2:Do you supply samples?

A:Of course, we supply samples for your testing.

Q3:How about sample fee?

A: We provide free stock samples less than 1KG, if you need special samples, please contact us and we could communicate.

Q4:How can you ensure quality?

A: We will produce samples before mass production, and do final inspections before shipment.